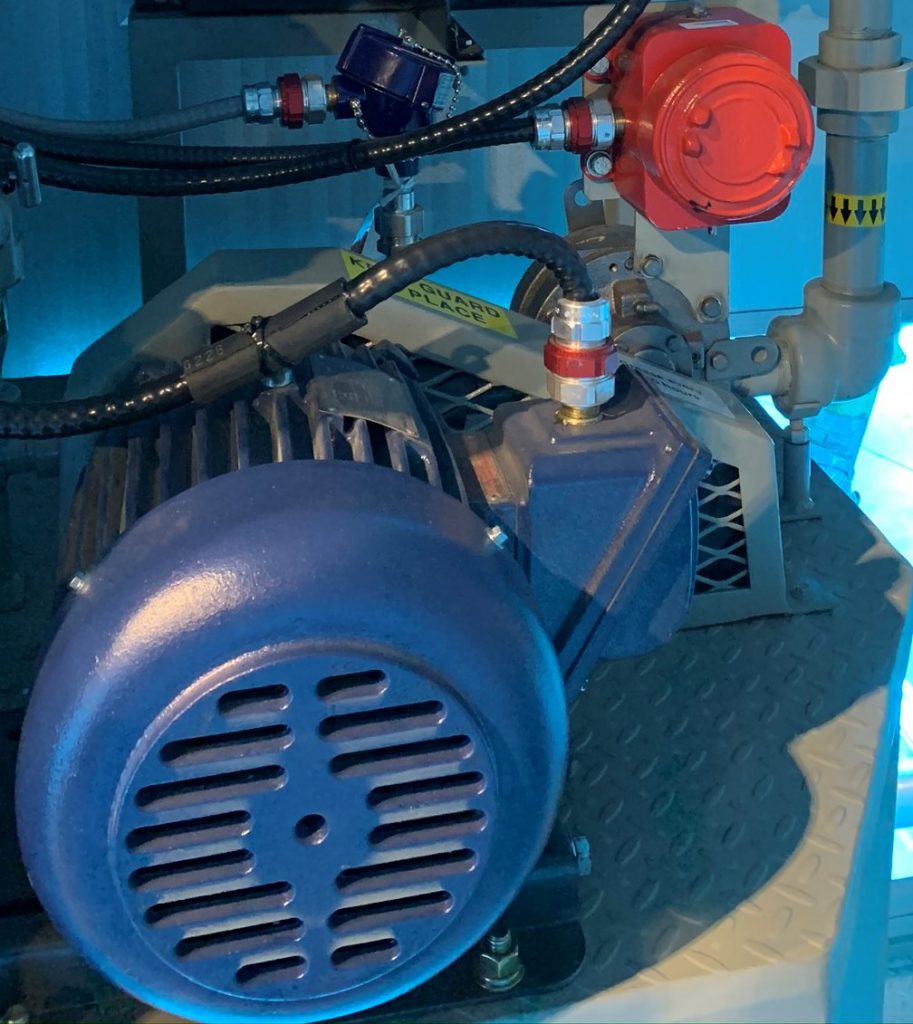

Blower compressors are a type of compressor that utilizes a blower to compress air or gas. They have several distinct characteristics, types, and advantages.

Blower compressors are known for their ability to provide a continuous flow of air or gas at relatively low-pressure differentials. They operate by drawing air or gas into a chamber and then using a rotating impeller or fan to increase the pressure.

Unlike traditional compressors, blower compressors typically produce less pressure per stage but are capable of handling larger volumes of air or gas.

Types of Blower Compressors

The main types of blower compressors:

Rotary lobe blowers. These use two or more lobes that rotate in opposite directions to compress air or gas.

Rotary screw blowers. They employ two intermeshing helical rotors to compress the air or gas.

Centrifugal blowers. Instead of using positive displacement, centrifugal blowers use centrifugal force to increase the velocity of air or gas, which is then converted into pressure.

The type of blower compressor to choose depends on several factors, including the specific requirements of your application, operating conditions, budget, and preferences.

Note the following points:

Flow rate and pressure requirements. Determine the volume of air or gas you need to compress and the desired pressure level. Rotary screw blowers are often chosen for higher-pressure applications, while rotary lobe blowers are suitable for applications requiring higher flow rates at lower pressures.

Operating conditions. Consider factors such as ambient temperature, altitude, and the presence of contaminants in the air or gas. Centrifugal blowers may be preferred for high-temperature applications, while rotary lobe blowers may be better suited for handling particulate-laden gases.

Energy efficiency. Evaluate the energy efficiency of different types of blowers. Rotary screw blowers are known for their energy efficiency, especially in applications with varying air demand, as they can adjust their speed to match the required airflow.

Maintenance requirements. Assess the maintenance needs of each type of blower compressor. Rotary screw blowers generally have fewer maintenance requirements compared to rotary lobe blowers, as they have fewer wearing parts.

Noise levels. Consider the noise levels produced by the blower compressor, especially if it will be installed in a noise-sensitive environment. Centrifugal blowers tend to operate more quietly compared to rotary lobe and rotary screw blowers.

Oil-free operation. Determine whether your application requires oil-free compressed air or gas. Rotary screws and centrifugal blowers can operate without oil lubrication, making them suitable for applications where oil contamination is a concern.

Cost. Compare the initial purchase cost as well as the long-term operating costs, including energy consumption and maintenance expenses, of different types of blower compressors.

By carefully considering these factors and consulting with a knowledgeable supplier or engineer, you can choose the type of blower compressor that best meets your specific needs and provides the most value for your application.

Why is it Beneficial to Buy Blower Compressors in Alberta?

Pros of blower compressors:

Continuous operation. Blower compressors are designed for continuous operation, making them suitable for applications where a steady supply of compressed air or gas is required.

Energy efficiency. They are often more energy-efficient than traditional compressors, especially in applications where a constant flow of air at low pressure is needed.

Low maintenance. Air compressors typically have fewer moving parts than other types of compressors, resulting in less need for frequent maintenance.

Quiet operation. Many blower compressors are designed to operate quietly, making them suitable for use in noise-sensitive environments.

Oil-free operation. Certain types of blower compressors, such as rotary screws and centrifugal blowers, can operate without the need for oil lubrication, which is advantageous in applications where oil contamination is a concern.

Blower compressors are preferred in applications such as wastewater treatment, pneumatic conveying, aeration, and other processes where a continuous flow of air or gas at relatively low pressures is essential.

High-Quality Blower Compressors in Alberta

Buying blower compressors in Alberta from GasPro Compression offers several advantages:

GasPro Compression specializes in compression equipment, including blower compressors. Our team has extensive knowledge and experience with this particular type of equipment, ensuring that you receive expert advice and support throughout the buying process.

GasPro Compression may provide customized solutions tailored to your specific requirements. Whether you need a standard blower compressor or a customized configuration for your unique application, our company can help you find the best solution.

Choosing a supplier like GasPro Compression located in Alberta offers convenience in terms of logistics and communication. You can easily coordinate delivery, installation, and ongoing support without dealing with long distances or time zone differences.

Establishing a relationship with GasPro Compression can lead to long-term benefits. We will be a trusted partner for your compression equipment needs, providing ongoing support, maintenance, and future equipment upgrades as your needs evolve.

GasPro Compression leads the industry in custom-designed VRU packages to meet our client’s needs. We offer a wide selection of components and horsepower to meet our client’s requirements.

You can order blower compressors and other products at an affordable price from GasPro Compression in Alberta at 403-443-8886.