Have questions about hydraulic gas compressors? Contact Gas Pro Compression Corporation specialists at 403-443-8886 or request a proposal.

GasPro Hydraulic Compressor

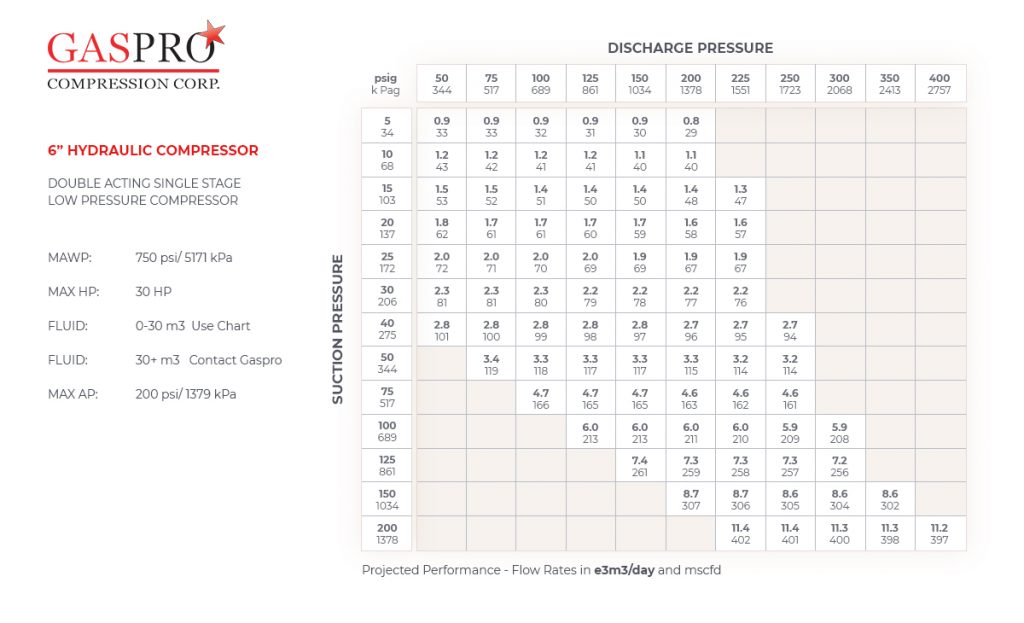

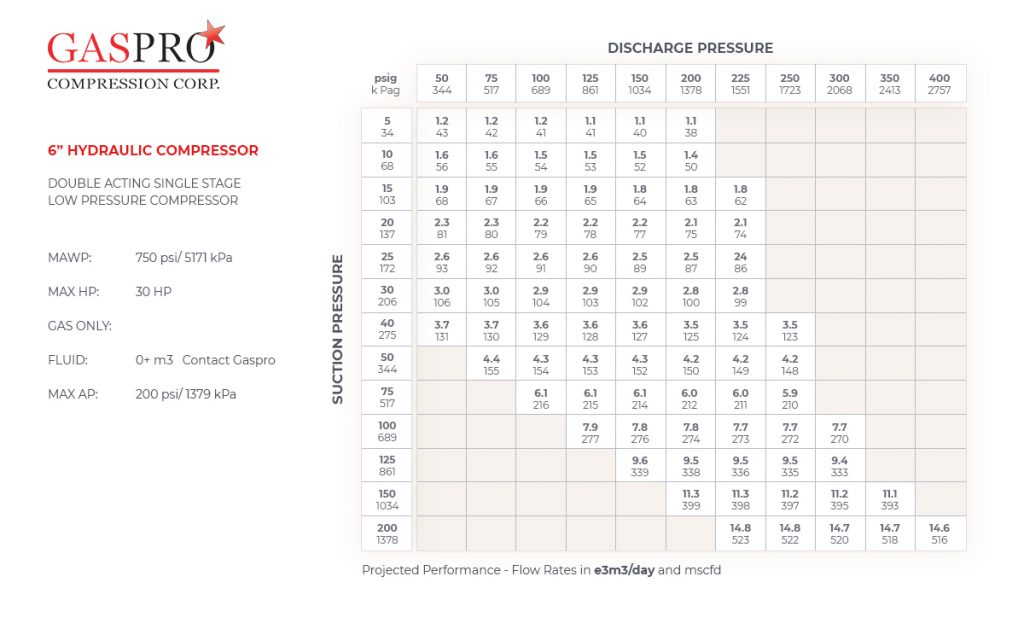

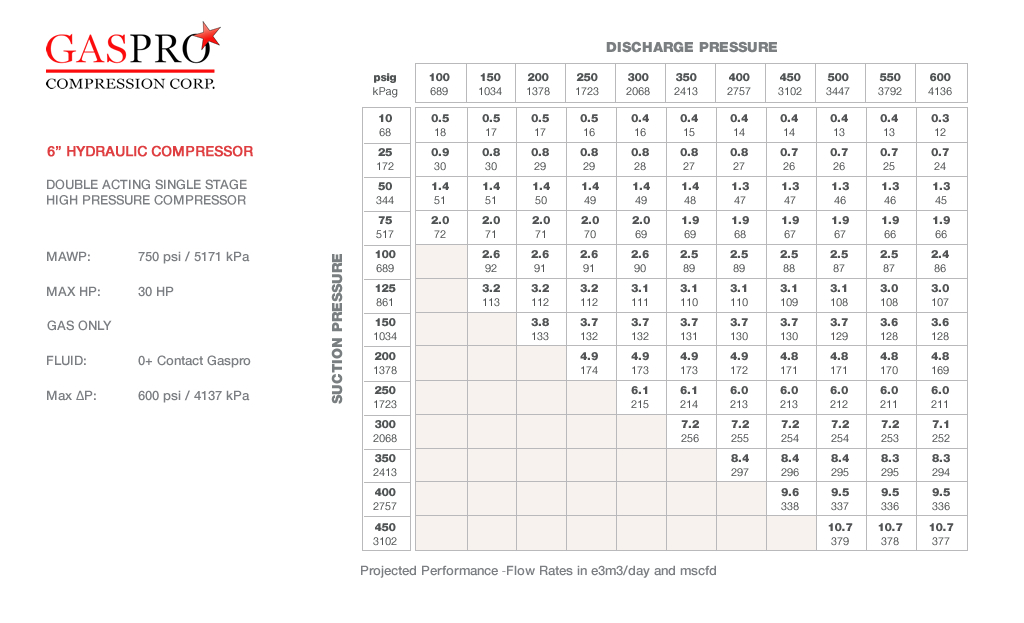

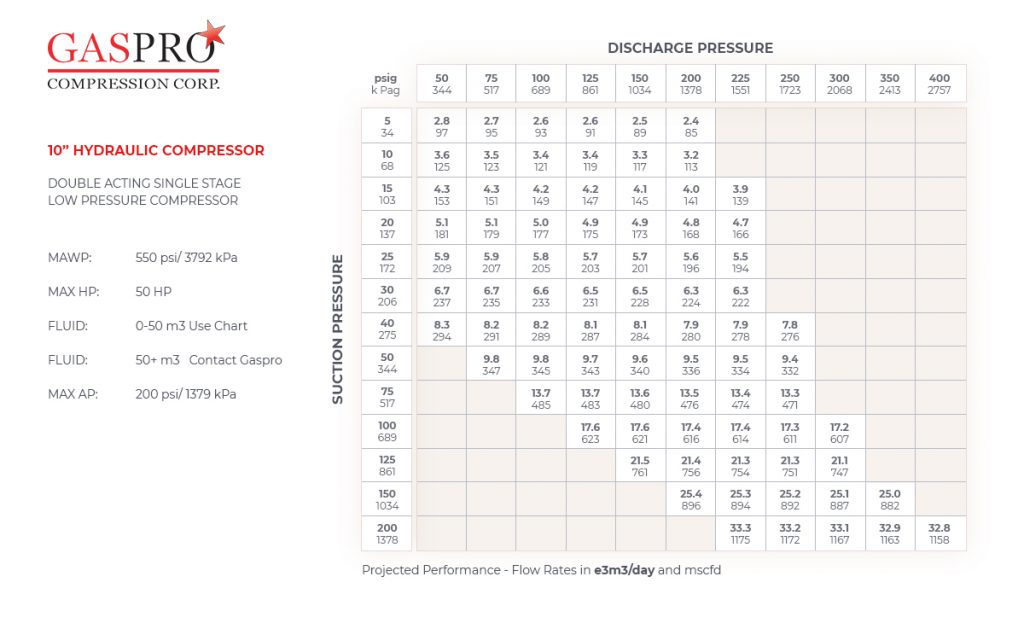

Introducing GasPro compression’s hydraulic driven compressor unit for low volume and high differential pressure applications.

GasPro has been able to develop a low cost, low maintenance hydraulic compressor – an unconventional way of gas compression system.

GasPro hydraulic compressors are able to capture gas at a very low flow rate eliminating the need of venting or flaring and improving well economics and efficiency. These compressors are equally good for meeting regulatory compliance and have a very small footprint.

Units are available for rent, rent-to-purchase, or purchase.

Contact Us now to learn more.

Frequently Asked Questions

A hydraulic gas compressor uses hydraulic pressure to compress gas in a controlled, efficient manner. Unlike traditional mechanical systems, it leverages hydraulic power to drive pistons or plungers that compress the gas. This design allows for high-pressure performance with fewer moving parts, reducing maintenance needs in field applications.

The key difference is the power source. While reciprocating compressors use gas engines or electric motors to drive compression, hydraulic gas compressors use hydraulic fluid pressure. This results in smoother operation, better efficiency in intermittent flow conditions, and simplified component design for harsh environments.

Hydraulic gas compressors can handle a variety of gases, including sweet and sour natural gas. They are often used in applications such as wellhead compression, vapor recovery, and gas lift, where reliable, high-pressure compression is required under variable flow conditions.

Yes. Hydraulic compressors are often engineered with corrosion-resistant materials and proper sealing systems, making them well-suited for sour gas environments. Gas Pro customizes each hydraulic gas compressor package to meet specific site conditions and regulatory requirements.

Because hydraulic compressors have fewer rotating parts, they experience less mechanical wear and tear. This translates to lower maintenance intervals, reduced failure points, and improved uptime – which is especially valuable for remote wellsite operations.