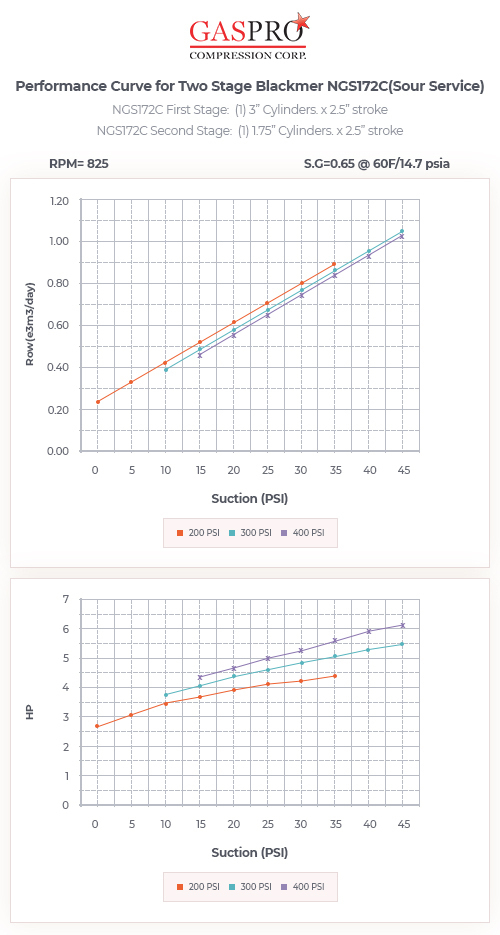

10 BHP – Two Stage

Blackmer Compressor

Make: Blackmer

Model: NGS172C

Type: Reciprocating

Min / Max Speed: 350-825 RPM

MAWP: 615 psia

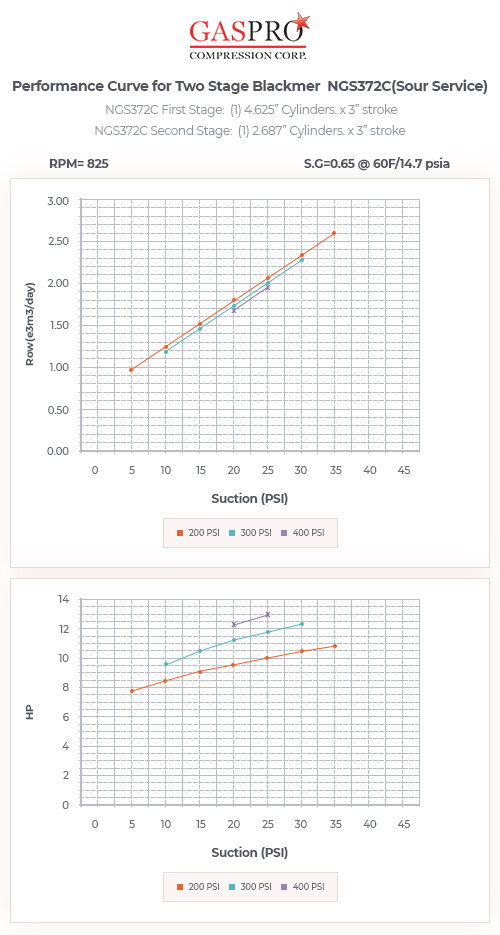

15 BHP – Two Stage

Blackmer Compressor

Make: Blackmer

Model: NGS372C

Type: Reciprocating

Min / Max Speed: 350-825 RPM

MAWP: 615 psia

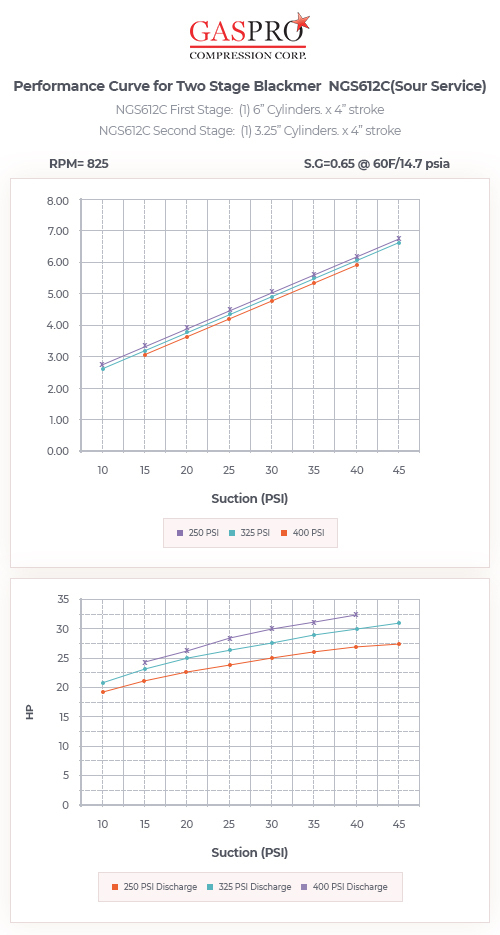

40 BHP – Two Stage

Blackmer Compressor

Make: Blackmer

Model: NGS612C

Type: Reciprocating

Min / Max Speed: 350-825 RPM

MAWP: 415 psia

Frequently Asked Questions

A two-stage reciprocating compressor compresses gas in two separate steps. The gas is first compressed in a low-pressure cylinder, then cooled and compressed again in a high-pressure cylinder. This process allows for more efficient compression, reduced heat buildup, and the ability to reach higher discharge pressures.

In sour gas applications, the two-stage reciprocating compressor is engineered with corrosion-resistant materials and proper sealing to safely handle hydrogen sulfide (H₂S) and other contaminants. Gas Pro customizes each package to meet environmental regulations and performance requirements for sour gas compression.

Gas Pro’s two-stage reciprocating compressor packages are custom-built for Alberta’s demanding oil and gas environments. With sour service-ready configurations, flexible rental or purchase options, and responsive local support, Gas Pro ensures long-term performance and regulatory compliance.

Yes. A two-stage reciprocating compressor is significantly more efficient at compressing gas to high pressures. Cooling the gas between stages reduces the work required for compression and minimizes mechanical stress, resulting in better overall energy efficiency and lower maintenance needs.

Yes. Gas Pro offers rental, lease-to-own, and purchase options for all two-stage reciprocating compressors. This flexibility allows producers to manage cash flow while maintaining high-performance compression at their sites.